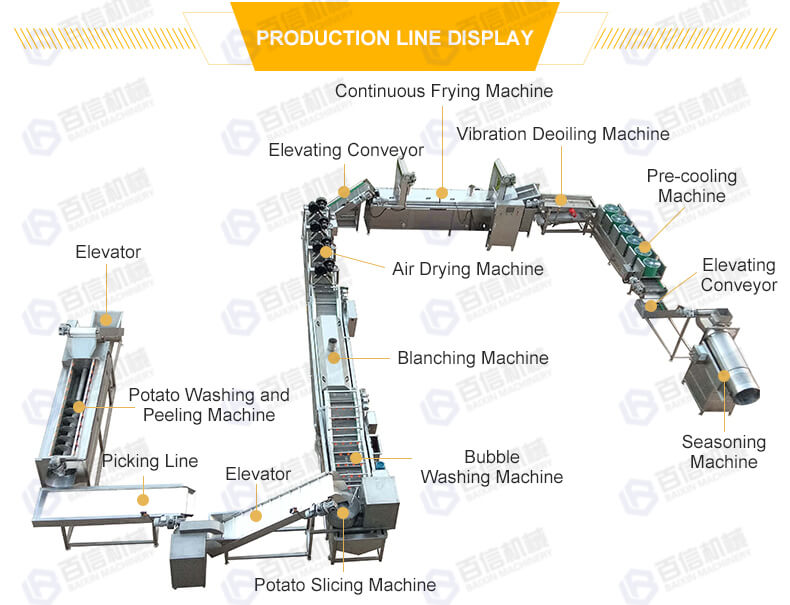

| No. |

Machine Name |

Function |

Advantage |

| 1 |

Elevating |

For elevating and conveying potatoes into

the next washing peeling machine |

1.The size can be customized

2.Conveying speed adjustable. |

| 2 |

Potato Washing and

Peeling Machine |

Thoroughly washing and peeling the potatoes |

1. Washing and peeling capacity can be customized.

2. The length of brush can be customized.

3.We use high quality brusher,even old potatoes

that are hard to peel can be peeled well.

4.Spraying system to clean the potatoes.

5.Spiral design to make sure automatic discharging.

6. The discharge speed can be adjusted.

7. The whole machine is made of 304 stainless steel. |

| 3 |

Picking Line |

For manually disposing the uncleaned places

and selecting the defective potatoes |

1.Picking table size can be customized

2.Conveying speed adjustable. |

| 4 |

Elevating |

For moving the cleaned and peeled potatoes

to the slicer |

1.The size can be customized

2.Conveying speed adjustable. |

| 5 |

Potato Slicing Machine |

Cutting the potatoes into slices,

sizes adjustable from 1-5mm |

1.Potato chips thickness 1-5mm can be adjustable.

2.Cutting surface is smooth without damage. |

| 6 |

Bubble Washing Machine |

Through high pressure waterflow and

water bubbles to impact and scrub the

potato slices to wash off the starch |

1.Remove the starch from the potato chips.

2.Strong water flow, bubble impact.

3.High pressure spraying system.

4.Filter system and water recycling system. |

| 7 |

Blanching Machine |

Through 60-95 degree hot water blanching to

inhibit the activity of the enzyme and maintains

the original vivid color of the potato slices |

1.You can use gas, electricity or diesel as power for

this machine depending on your needs.

2.It can effectively protect original vivid color of the potato chip.

3.You can add additives during blanching process. |

| 8 |

Vibration Dewatering Machine |

Through vibration to remove the surface water and

also to transport the potato slices uniformly to

the next machine |

The de-water time is adjustable. |

| 9 |

Air Drying Machine |

Through high pressure wind blowing for pre-cooling

and removing the excess water in short time,

effectively prevent the fried oil jumped phenomenon |

1.The multi-layer mesh belt conveyor belt and

special fan outlet completely remove

the moisture on the surface of the potato slices.

2.Fan can be adjusted up and down. |

| 10 |

Elevating Conveyor |

For elevating and conveying the potato slices

into next fryer machine |

1.The size can be customized

2.Conveying speed adjustable. |

| 11 |

Continuous Frying Machine |

For quick frying the potato slices

around few minutes in 180°oil |

1.Automatic lifting system, easy to clean.

2.Double mesh belt transmission to avoid the chips floating.

3.Oil filter and recycling system to automatically and

continuously filter the oil residue to extend the service life.

4.Electric or gas heating. |

| 12 |

Vibration Deoiling Machine |

Through high frequency vibrating to

achieve deoiling purpose, and also to

convey the potato slices uniformly to next machine |

The de-oil time is adjustable. |

| 13 |

Pre-cooling Machine |

Through high pressure wind blowing for pre-cooling and deoiling the potato slices |

1.The multi-layer mesh belt conveyor belt

and special fan outlet completely remove

the oil on the surface of the potato slices.

2.Fan can be adjusted up and down. |

| 14 |

Elevating Conveyor |

For moving potato chips to seasoning machine |

1.The size can be customized

2.Conveying speed adjustable. |

| 15 |

Seasoning Machine |

Spread the seasoning evenly over each potato chip |

1.With spice tank, the flow of spice adjustable.

2.You can add additives any you want even liquid

such as oil, water etc.

3. Seasoning time can be controlled. |

| 16 |

Automatic Weighing

Packing Machine |

For packing the finished potato chips |

It can fill Nitrogen automatically, automatic weighing,

automatic sealing and automatic packing. |