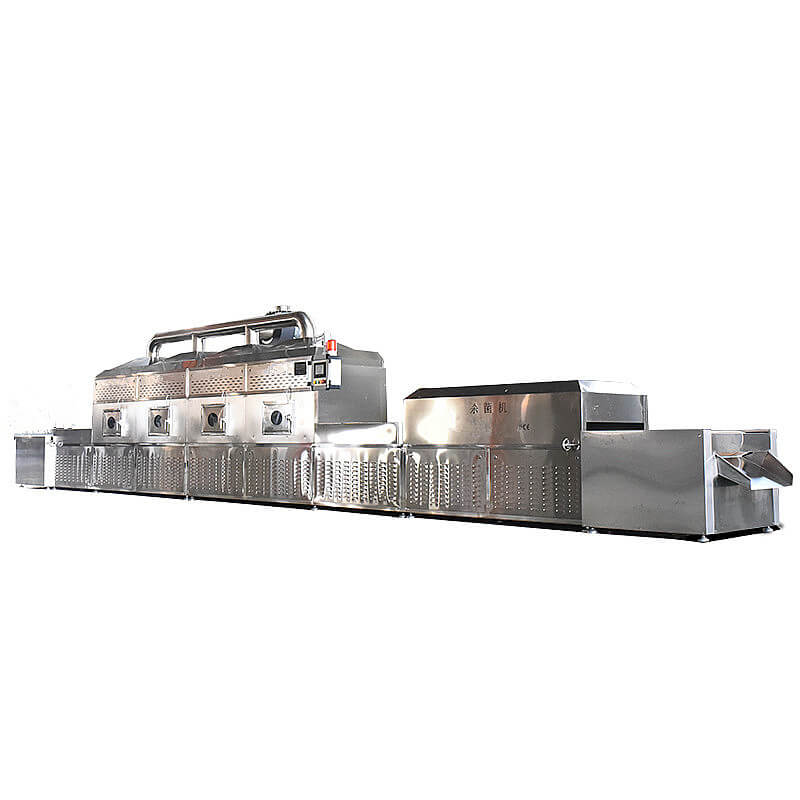

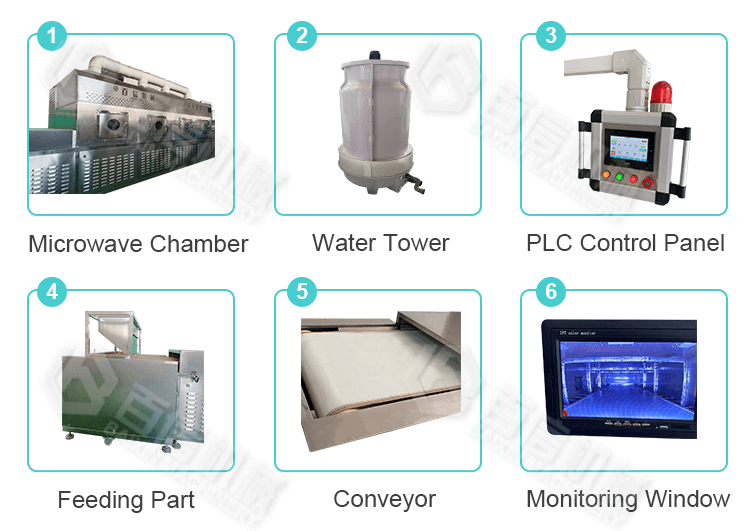

Microwave dryer is suitable for drying, sterilizing, deenzyme and puffing of various foods. E.g:

1. Drying and sterilization of meat: chicken, fish, beef, sausage, etc.

2. Drying and sterilization of various fruits: mango, banana, peach, apricot, etc.

3. Drying and sterilization of various vegetables: onion, cassava, cardamom, ginger, garlic, etc.

4. Puffing on various foods: potato chips, shrimp chips, dried fish, etc.

5. Heating, drying and sterilization of various condiments.

6. Microwave food dehydrator is suitable for thawing various quick-frozen foods.

7. Microwave dryer is suitable for fast heating of fast food.

Field of Application of microwave dryer