How to Make Dried Flowers/How To Dry Dehydrate Flowers

Method of making dried flowers:

There are many uses for flowers. In addition to viewing, they can also be used to make essential oils, snacks, flowers, etc. The economic value cannot be underestimated. With the development of economy, flowers have appeared in the public's field of vision, and it has become more and more popular among the public. There are many drying methods for flowers, the common ones are sun-drying, air-drying, and drying by a dryer. Among them, the sun-drying method and air-drying method can save costs, but if it encounters rainy weather, the flowers are prone to mold, the efficiency and yield are low, and the shelf life is relatively short. Generally, insects may grow in 2-3 months. The reason is that some surface eggs were not killed before drying. Therefore, the natural drying method is not suitable for the commercial production of flowers. Using a dryer to dry the flowers can effectively avoid these problems, and the quality and color of the products produced are very good. Let us understand the specific methods of drying and storing flowers.

How to dry flowers in small batches at home:

1. Sun-drying:The flowers can be dried in the sun. Place the collected flower stalls on a clean concrete floor and then dry them in the sun. This process takes about 7-10 days. Collect it after it is completely dry. However, the petals of flowers dried in the sun are easy to fall off, and the aroma is not strong.

2. Air-drying:

Air-drying is the simplest and most commonly used method for drying flowers. Choose a warm, dry, and well-ventilated room. The indoor temperature should not be lower than 10°C and let it dry slowly. This method takes a long time, about 20 days. The flowers produced in this way has good color and a strong fragrance, but it is prone to bugs when stored.

3. Steam first and then dry:

Steam the flowers in the pot for 20 minutes, then take them out and dry them in the sun. Generally, they can be dried in 3-4 days. After high-temperature sterilization, the flowers are easy to store, and the petals are not easy to break. This method is the best choice for homemade flowers.

4. Microwave oven drying method:

Drying flowers in a microwave oven is a new method, which is characterized by a short time. The drying time in a microwave oven depends on the power of the microwave oven and the number of flowers.

How to use the dryer to mass produce dried flowers:

1. Picking:Choose flowers with full petals and fresh colors

2. Color protection treatment:

The main methods include high-temperature steam, microwave curing, and blanching machine. The high-temperature steam method can increase the stability of the pigment, and can also kill or inactivate the enzyme activity in the material.

3.Put the flowers into the material layer by layer. Take the 6P drying and dehumidification integrated host with 25 cubic meters of drying room as the standard model, which can put about 1800 kg of fresh flowers at a time. The whole drying room can be loaded with 8 material trucks, each of which is divided into 12-14 layers, and the interval between layers is about 8-12cm. The material truck must use a 304 stainless steel screen to avoid production pollution to the material.

4. Drying:

(1) Adjust the drying mode, and no moisture will be discharged at this stage. Dry for 1 hour;

(2) Set the temperature to about 50°C, turn on the dehumidification, and reduce the humidity to 40%;

(3) Increase the temperature by 10°C and lower the humidity to 30%;

(4) The temperature remains unchanged, and the humidity is reduced to 20%;

(5) Adjust the temperature appropriately and the humidity down to 15%. Check the dryness of the stamens.

5. Collect flowers:

After the flowers are dry, the running program ends and the equipment will automatically shut down. Leave the dried flowers to cool, and then collect the flowers. Be careful not to crush the flower shape when collecting flowers.

Precautions:

The appearance of the flowers is the selling price. You must pay attention to moisture removal during the drying process. If the moisture removal capacity is not enough, you can consider installing a strong exhaust fan.The wet-to-dry ratio of flowers is about 4:1. Do not exceed the recommended loading amount when installing flowers, so as not to affect the shape of the flower and the appearance of the dried flower.

Preservation method of Dried flowers:

You can choose the preservation method of kraft paper bag or tin + aluminum foil bag. Pack the flowers with a kraft paper bag, then seal the mouth and store it in a dry, cool place.

Secondly, you can also use aluminum foil bags. First, pack the flowers in an aluminum foil bag, squeeze out the air in the bag, then seal the mouth of the bag, put it in an iron pot, cover the lid, and finally put it in the refrigerator to keep it at the temperature. It should be at 0~5℃.

In addition, you can also choose porcelain jars, which can also maintain the quality of dried flowers. Since dried flowers still contain about 5% to 10% moisture, it is best not to put them in plastic bags or transparent glass bottles.

Precautions:

The flowers should be kept in a dry and cool place as much as possible. Different types of dried flowers should not be mixed and stored because they will absorb each other's fragrance. In addition, the same type and different purchase periods should also be stored separately to avoid accelerated loss of the flower's aroma.

Shelf life of dried flowers:

In principle, we can enjoy the flowers within 3 months after buying them back, and their fresh fragrance can reach the best condition.

If you need to dry flowers in large quantity, Baixin Machinery’s drying equipment is a good choice. Baixin Machinery is a manufacturer specializing in the production of dryers. It has 20 years of rich experience. For flowers drying, it has professional drying equipment and mature drying technology to ensure the perfect drying effect.

Baixin Machinery’s most popular flowers dryers are heat pump dryers and continuous mesh belt dryers.I would be happy to introduce these two dryers in detail for you:

1:The first method:flowers heat pump dryer

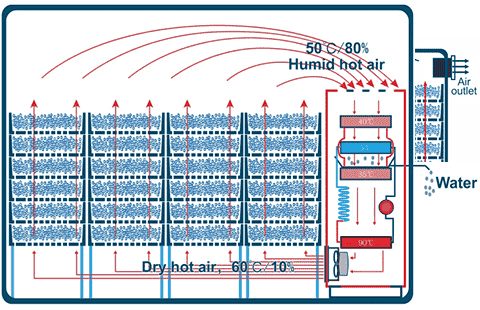

Household Commercial All-in-one drying equipment without installation for any materialDrying essence is take moisture away, but takes away the moisture temperature is not the most critical factor. The key for drying is depending on relative humidity within certain space, Baixin Company took advantage of the dry essence, originality developed a "Closed Cycle" dryer, changed the traditional heat pump dryer "bake" to "dehumidifier”. Its several advantages were unmatched by the traditional heat pump dryer.

Baixin Food Dehydrator has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation and removable. it is the best drying equipment for small firms, drying experiment and scientific research. The users only connect the power to use, is the easiest operation heat pump dryer.

2:The second method: flowers continuous mesh belt drying machine

Large amount of dehydration 200-5000kg/h flowers drying machine continuous automatic work easy operationFlowers dryer machine is a kind of continuous production drying equipment, the main heating way has electric heating, steam heating, hot air heating. Its main working principle is to spread the material evenly in the network. The material is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the material. so as to achieve the purpose of drying.

The operation temperature is 40-120 degree centigrade. And the dry cycle is 1-5 hours.

Flowers drying video:

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.