Ginger Powder Processing Process / Ginger Powder Processing Machinery

Ginger Powder Processing Process / Ginger Powder Processing Machinery

Ginger is widely used in food, beverage, cosmetics and spices. In order to meet the cooking needs of different families, restaurants and food processing plants, ginger is often processed into ginger powder. What are the manufacturing techniques of ginger powder? How to make ginger powder?If you make ginger powder at home, the process of making ginger powder is not complicated.

First, you need to prepare fresh ginger, wash and peel it.

Then, slice ginger,

Secondly, put the ginger slices in the oven (dry for 6 hours) or dry in the sun for 2-3 days to get the dried ginger slices.

Finally, the dried ginger slices are beaten into powder to get ginger powder.

The above is how to make ginger powder at home. If you want to start the ginger powder business and make a large number of ginger powder, you first need a professional ginger powder production line. Next, I'll share with you the process flow of ginger powder production in the ginger powder factory.

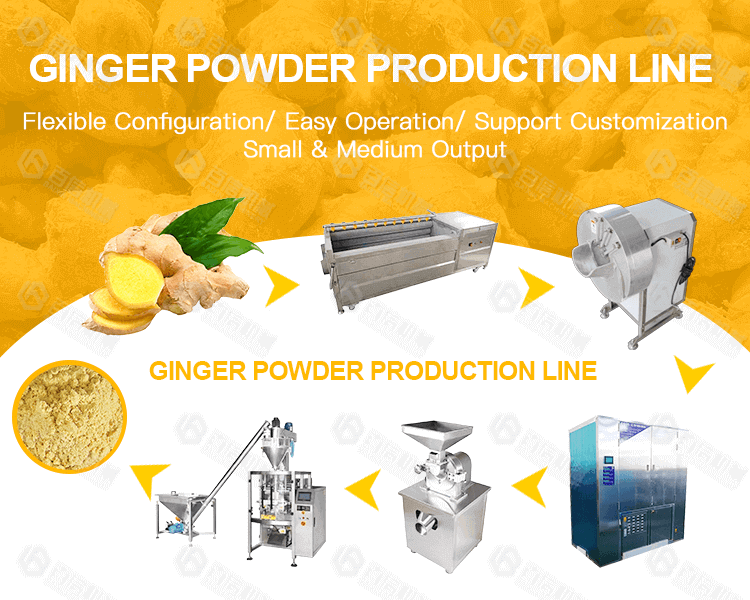

The ginger powder production line is equipped with different ginger processing machines according to the output of ginger powder. Next, I share the process flow of two production lines: 50-100kg / h small output semi-automatic ginger powder production line and 500-800kg / h large output full-automatic ginger powder production line.

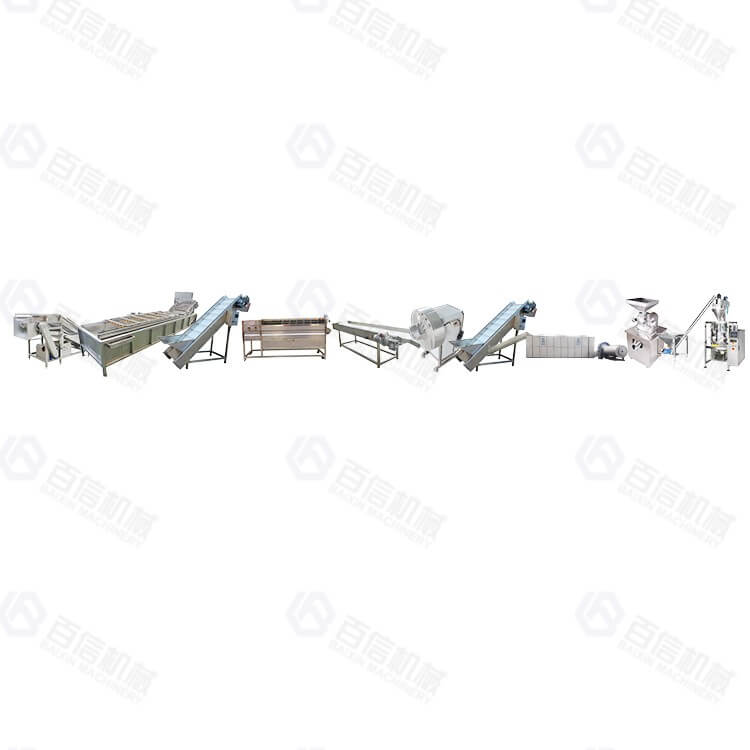

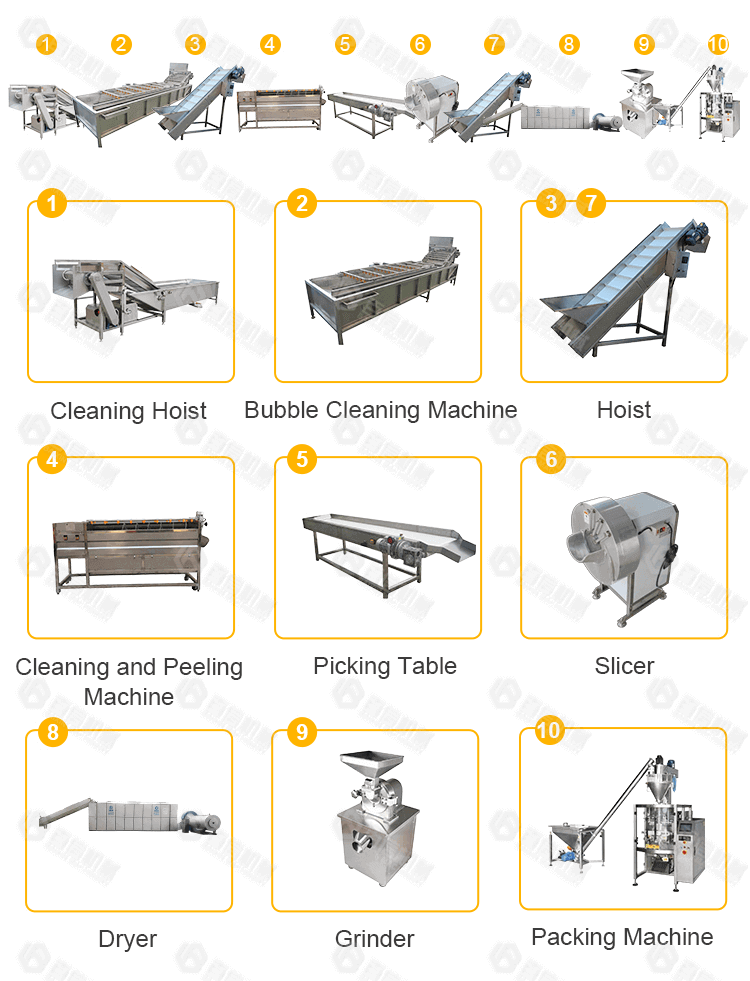

500-800kg/h large output full-automatic ginger powder processing line:

The ginger powder processing line uses ginger as raw material, and processes ginger into ginger powder through processing techniques such as cleaning, peeling, slicing, drying, and grinding. Meet the culinary needs of different households, restaurants and food processing plants.Processing ginger into ginger powder can increase the added value of ginger in the ginger planting industry, and reduce the ginger loss and storage and transportation costs caused by ginger price fluctuations. This is the best choice for the ginger powder business!

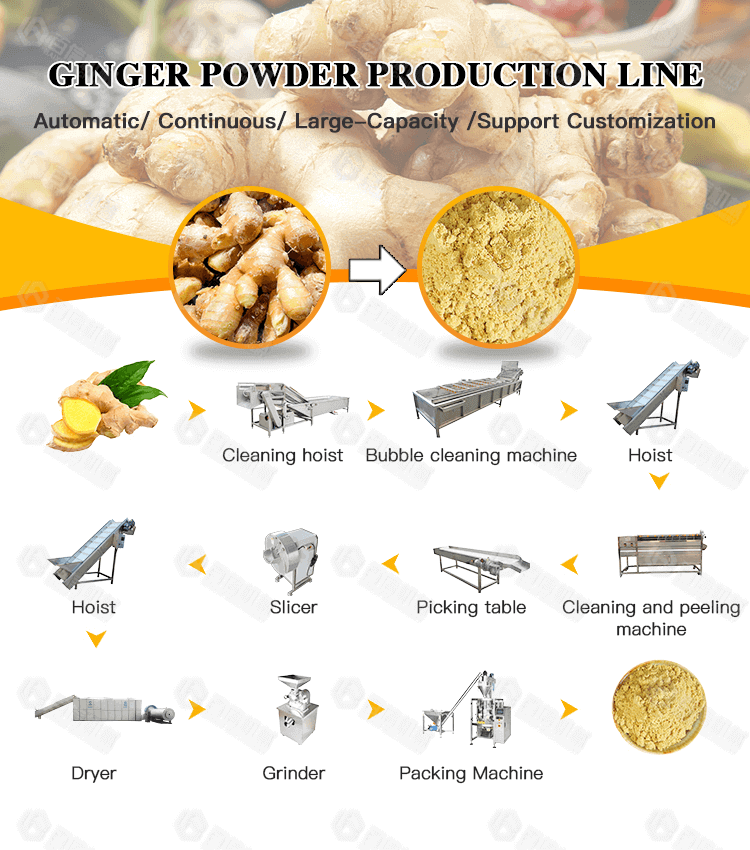

Ginger powder processing line flow chart:

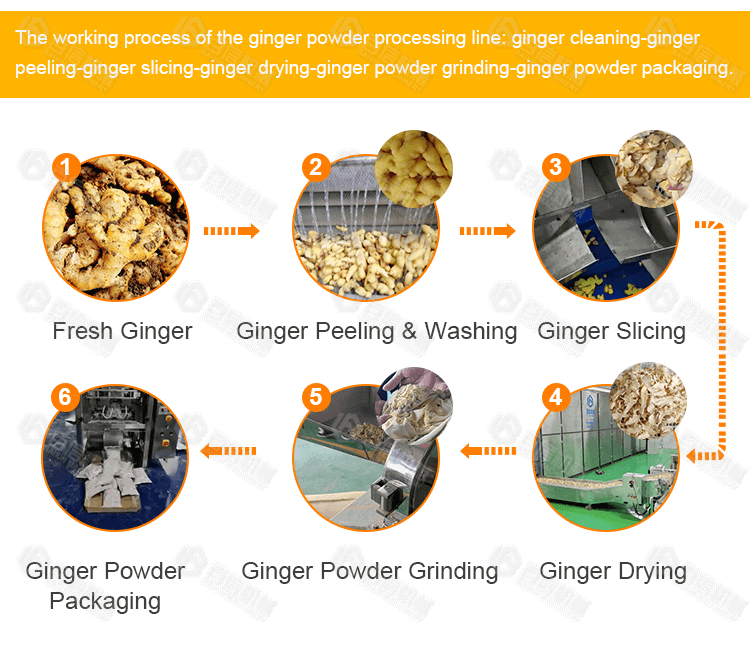

The working process of the ginger powder processing line: ginger cleaning-ginger peeling-ginger slicing-ginger drying-ginger powder grinding-ginger powder packaging

Ginger powder processing line component:

Ginger cleaning machine: It is used to clean the dirt, dust and other impurities attached to the surface of ginger root. The ginger is rolled, washed and transported under the action of high pressure water flow and powerful air bubbles, and then sent to the next process.

Ginger peeler: for cleaning and removing the epidermis. The specially designed screw feeding structure is adopted to realize fully automatic work.

Ginger slicer: The thickness of ginger slices is uniform, and the slice thickness can be adjusted as needed.

Ginger air dryer: effectively remove the moisture on the surface of ginger slices after cleaning, greatly shorten the drying cycle, suitable for assembly line operation.

Ginger slice dryer: adopts multi-layer moving stainless steel mesh belt, automatic loading and unloading, saving a lot of labor costs. Flexible heat source selection: Coal, wood chips, natural gas, diesel, propane, electricity etc.

Ginger powder making machine: Grind dried ginger slices to a fineness of 10-120 mesh. The ginger grinder is air-cooled or water-cooled and can work continuously for a long time.

Ginger powder packaging machine: Generally speaking, ginger powder business requires automatic ginger powder packaging equipment. The ginger powder packaging machine has a PLC control system, which is intelligent and controllable, and can be quickly adjusted according to customer packaging requirements. Packaging weight and quantity are automatically adjusted.

500-800kg/h automatic ginger powder processing line parameter :

| 500-800kg/h automatic ginger powder processing line | ||||

| Number | Name | Power | Size | Output |

| 1 | Cleaning hoist | 0.37KW | 3200*1050*2500mm | 500-1000kg/h |

| 2 | Bubble cleaning machine | 3.37KW | 3000*1020*1350mm | 1000kg/h |

| 3 | Hoist | 0.55KW | 1500*800*1600mm | 500-1000kg/h |

| 4 | Cleaning and peeling machine | 2.75KW | 3050*700*1600mm | 1000kg/h |

| 5 | Picking table | 0.37KW | 3000*740*1100mm | 500-1000kg/h |

| 6 | Slicer | 1.1KW | 690*560*880mm | 500kg/h |

| 7 | Hoist | 0.55KW | 1500*800*1600mm | 500-1000kg/h |

| 8 | Dryer | 20.12KW | 9000*2000*2500mm | 500-800kg/h |

| 9 | Grinder | 15KW | 1200*1000*2000mm | 500-700kg/h |

| 10 | Packing Machine | 3.5KW | 3000*1500*2600mm | 30-60 packs/min |

| The ginger powder processing line can be equipped according to the user's requirement and the production demands. | ||||

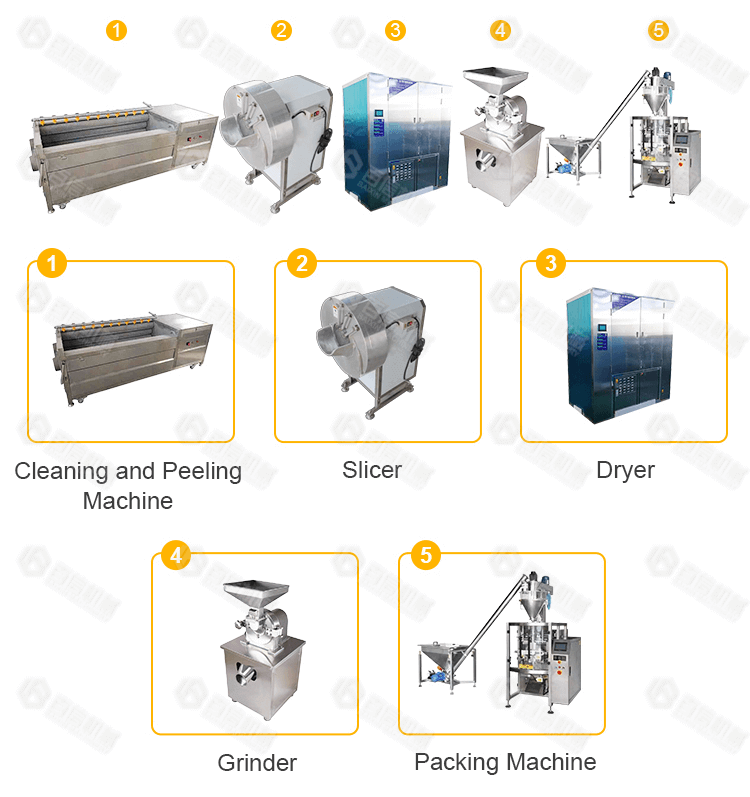

50-100kg/h small output semi-automatic ginger powder processing line:

Ginger powder processing line component:

50-100kg/h ginger powder processing line parameter:

| 50-100kg/h small output ginger powder processing line | ||||

| Number | Name | Power | Size | Output |

| 1 | Cleaning and peeling machine | 0.75KW | 690*430*860mm | 100kg/h |

| 2 | Slicer | 1.1KW | 690*560*880mm | 300kg/h |

| 3 | Dryer | 3KW | 2100*930*2100mm | 50-100kg/h |

| 4 | Grinder | 5.5KW | 750*600*1260mm | 30-150kg/h |

| 5 | Packing Machine | 1.6KW | 700*750*1650mm | 30-60 packs/min |

| The ginger powder processing line can be equipped according to the user's requirement and the production demands. | ||||

Do you want to start a ginger powder business? If you want to get the ginger powder making machine price and more professional questions about ginger powder making, please feel free to contact us online!!

Ginger powder processing line video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.