How to Dry Sausage/Dehydrate Sausage in a Dehydrator

Introduction to sausage:

Sausage refers to meat products with Chinese characteristics that are made from meat as raw materials, cut into cubes, supplemented with auxiliary materials, and poured into animal casings to be fermented and matured. It is a large category of meat products with the largest variety in China. Sausage is a kind of raw and dried intestine products made by putting pork into the casing made of pig small intestines and going through the processes of compression, dehydration and drying.

Sausage processing steps:

1. Sausage ingredientsGood Lap-mei generally uses the freshest local pork of the day, fresh skinless pork leg, fat and lean is about 3 to 7. The choice of ingredients is fresh. The full use of ingredients is a prerequisite for whether the la-mei can be attractive. Then cut the fat and lean meat separately. The lean meat can be cut into larger slices, and the fat meat can be cut to half the size of the lean meat.

2. Raw material pickling

Generally, after the pork is washed in warm water, add white wine sterilization, salt, sugar, soy sauce and other seasonings in a certain proportion, mix well, marinate for at least 6 hours, and mix in different proportions of seasonings. If you like spiciness, you can add chili or Chinese pepper with different spiciness according to the taste.

3. Making casings

Casings are generally made from the internal fat and fiber of pig small intestines, and then they are marinated and kept fresh or put in the refrigerator to be frozen and kept fresh for later use.

4. Enema

Before enema, soak the casing in warm water, wash it or soak it in ginger onion water for one hour to remove the fishy. Tie one end of the casing with a white thread. Put the other end on the mouth of the cleaned funnel, then put the flavored meat into the funnel, and slowly pour it into the casing. Be careful not to twist the casing when you put on the casing. When filling the sausage, the thickness should be uniform and the tightness should be the same. Don't be too tight, just slightly elastic.

5. Post-enema treatment

First fill the casings completely, tie a slip knot at the end, pat the sausage appropriately to make the meat firmer, so that it can be deflated before filling; then use hand to segment the sausages and use iron nails to deflate the sausages section by section. Exhaust, knotted section by section with cotton thread. The rope for tying sausages usually uses natural dried corn husks instead of any rope made of chemical fiber.

Sausage drying process:

During the drying and dehumidification process, Lap Mei must not only remove the moisture in the material, but also retain the original color, fragrance, taste, shape and other sensory indicators in appearance to ensure that it will not deteriorate or mold during the future shelf life. Drying and dehumidification are closely related. Traditional sun-dried wax flavour needs to rely on dry autumn breeze and natural sunlight. It usually takes 15 days. In bad weather, the wax flavour will have a greasy smell, improperly handled and even smell of slaw, which is easy to mold and deteriorate.1. Pre-heat treatment

Within two hours after putting the bundled sausages into the heat pump drying room, the temperature quickly rises to 60°C-65°C without dehumidification. The main purpose of this process is to function as a fermentation process to prevent the meat from changing color and taste. After the warm-up time, adjust the temperature to 45°C-50°C, and control the humidity within the range of 50-55%. Note: When the sausage is dried, the temperature should not be too high. When the temperature is higher than 65°C, the sausage will drip oil. Moreover, if the temperature is higher than 68℃ for a long time when the sausage is dried, the sausage will be rotten.

2. Stereotype

Grasp the control of the hair color period and the shrinkage setting period. The temperature is controlled at 52°C- 54°C, the humidity is controlled at about 45%, and the time is 3-4 hours. The sausage gradually changes from light red to bright red, and the casing begins to shrink. At this time, you must pay attention to the appearance of the hard shell, which can be used alternately with cold and hot, and the effect is good.

3. Strengthen drying

The main limiting factor at this stage is temperature. In order to strengthen the drying speed, the temperature must be increased to 60°C-62°C, the drying time is controlled at 10-12 hours, and the relative humidity is controlled at about 38%. The humidity in the final drying of the sausage is controlled below 17%.

After the adjustment and control of the drying equipment indicators in the above stages, the baked sausage has a smooth color, natural red, white fat, uniform stripes, close-fitting, compact structure, and flexible bending; the cut surface is smooth and has no voids or impurities. The hand feels good and the meat smells fragrant, which not only improves the drying quality of sausages but also increases the yield, saves time and effort, and is no longer affected by the weather.

Precautions:

1. Sausages are not only a drying process, but also a process of fermenting sauces to taste. Good sausages usually need to be dried for 40 hours.

2. The starchy sausage must be high temperature and a lot of moisture in the early stage, and the initial drying must be achieved in the first 10 hours.

3. Many people like to make their own sausages, but they cannot be eaten fresh. In addition to a longer time and more tasty, the most important thing is that nitrite reaches its highest value in 7-14 days. After 2 weeks, the content begins to decrease, and after 20 days, the content will drop to the lowest level. Therefore, it is recommended that if the sausage is dried at home, it is best to eat it after 20 days.

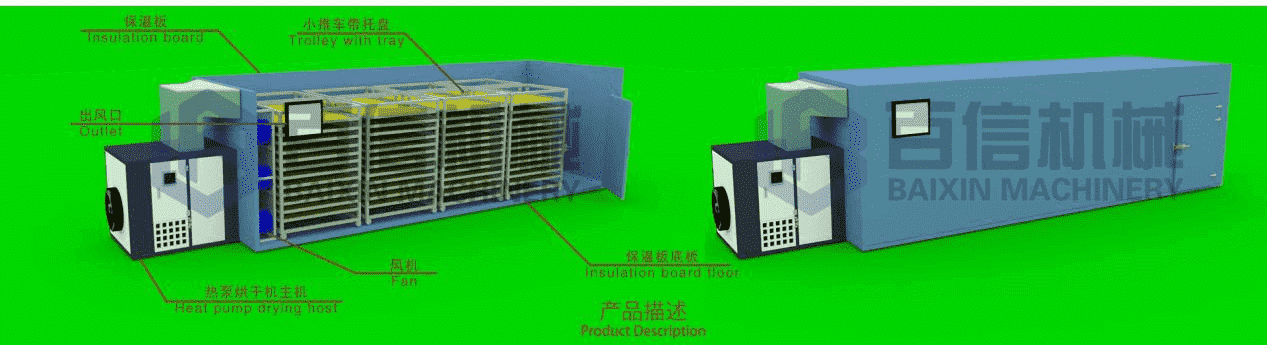

Recommendation of sausage dryer/drying machine

Commercial 100-3000kg/h large amount of dehydration wide application and easy operation

Heat pump drying machine use the principle of inverse Carnot cycle. It absorbs low-temperature heat energy in the air, which becomes high-temperature heat energy after efficient heat collection and integration by the heat pump system, and is transported to the drying room for cyclic heating and drying of materials.It refers to exhausting the hot and humid air in the drying room directly to the outside of the drying room through dehumidification device, and then replenishing natural fresh air.

Hot air circle drying machine belongs to high temperature heat pump unit. Its working principle is: the working fluid of the heat pump is compressed by the compressor, becomes high temperature and high pressure gas, enters the condenser, condenses and liquefies the heat, and is used for air heating in the drying room. The moisture in the material is vaporized and evaporated by the form of hot air, and the evaporated water vapor is discharged by the moisture discharge system, thereby achieving the purpose of drying the drying material.

Sausage drying video:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.